Welcome to the Exactaform Learning Centre - your central source for everything related to high-performance tooling. From application tips to technical insights, this is where you’ll find the resources to machine smarter, solve problems faster, and get the most out of your tools.

Exactaform. Made different. Delivered better.

Aluminium is a lightweight and highly machinable material, but its softness and tendency to generate built-up edge (BUE) present unique machining challenges.

Over the last four decades, we’ve grown to employ over 70 individuals in our purpose-built facility in Coventry.

These finishing endmills are engineered for precision and surface quality in composite and non-ferrous material applications.

Part of the Aero-CARB Metric Range, these ballnose slot drills offer a cost-effective upgrade for machining CFRP and other composite materials.

Engineered as part of our Aero-CARB Metric Range, these drills are designed to deliver excellent performance and consistency when drilling composite materials.

The 10˚ Helix Diamond Coated Endmills are engineered for high performance and durability in demanding applications.

Some manufacturing hurdles need a bespoke, tailored approach. This is where Exactaform come in.

The eco-cut ball nose is engineered to handle non-ferrous materials and abrasives like graphite and composites.

A bit reamer is a precision rotary cutting tool used to enlarge and refine a pre-drilled hole to its final size. It ensures a perfectly round shape and a smooth surface finish while maintaining tight dimensional tolerances.

Made from tungsten carbide combined with a cobalt binder, it offers exceptional hardness and heat resistance, making it ideal for drilling applications amongst others in tough metals such as stainless steel, nickel alloys, and carbon steel.

CFRP is an abrasive, layered composite material that requires complex machining capabilities to overcome delamination, fibre pullout, and rapid tool wear.

Cubic Boron Nitride (CBN) is a synthetic superhard abrasive material, engineered as an alternative to diamond-based tools like PCD.

Visit here to check out our Case Studies!

Exactaform are a constantly growing company, often looking for new additions to our amazing team. If you think you would fit well with our culture and values, feel free to apply to one of our open positions.

On September 21st, Exactaform’s headquarters buzzed with excitement and energy as we welcomed our team members and their families to our annual Family Day.

A cutter end mill, commonly referred to as a milling cutter or end mill, is a rotary cutting tool used in milling applications to remove material and shape a workpiece.

Custom end mills are specialised cutting tools designed to meet specific machining capabilities that cannot be addressed by standard, off-the-shelf tooling.

Drilling is a core machining process used to produce accurate, clean, and burr-free holes in everything from lightweight composites to high-strength metals.

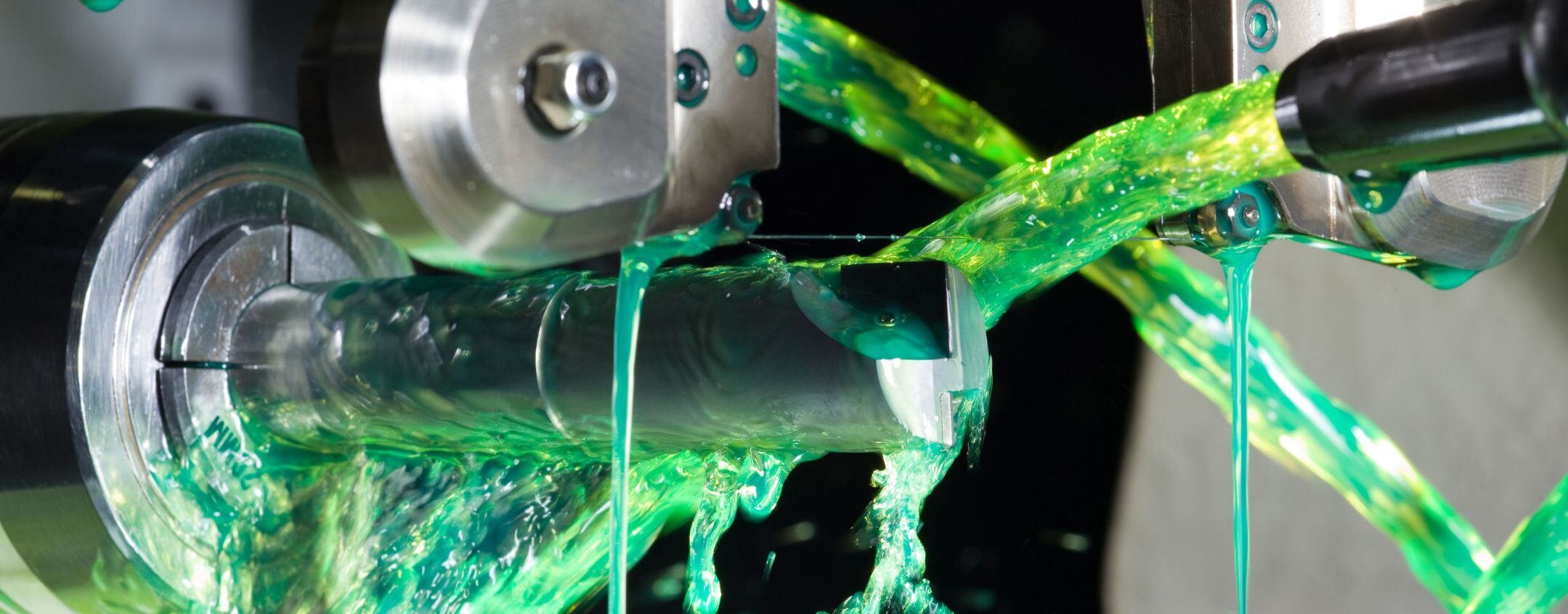

Diamond coated tools provide enhanced wear resistance and increased tool life for machining a wide range of abrasive tough materials like aluminium and composites.

The combination of point geometry and diamond coating gives superior results compared to conventional tools with both tool life and delamination.

The 4 Flute Diamond Coated drill is a great alternative to our standard diamond coated drill.

If you’re looking for improvement when milling CFRP or composites, but you need a more cost-effective option, then our diamond coated range is the ideal choice.

An alternative to our PCD Ball Nose Milling Cutter, this cost-effective tool provides significant increases in tool life when compared to standard carbide tools.

Exactaform Cutting Tools USA was established in 2017 to expand our presence in the North American market and better serve our growing customer base.

we have developed what we believe is the best option that provides a sensible combination of durability, stability, and simplicity as a platform for cartridge style PCD milling.

A cost-effective PCD solution designed for machining modelboard, graphite, composites, and aluminium.

eco-cut is a PCD tool range created for the needs of model board, graphite, plastic, aluminium and composite machining.

Combining the superior properties of PCD and the geometry traditionally used in carbide cutters, the Exacta-burr is the only choice for high volume manufacturing.

Achieve flawless surface finishes with our high- performance finishers, perfect for precision applications.

Designed for rapid material removal, our aluminum roughers deliver excellent efficiency.

These end mills provide superior short chip control and are highly effective where long chips compromise process stability.

Optimised for challenging cuts, these roughers ensure clean chip evacuation for smoother operations.

Our roughing end mills will cope with the most demanding processes encountered in the modern machining environment.

Engineered for precision, our finishers produce superior surface quality for titanium and nickel applications.

These end mills provide superior short chip control and are highly effective where long chips compromise process stability.

A hand reamer is a manually operated, cylindrical cutting tool used to finish and accurately size existing holes.

Fight against Hand-Arm Vibration Syndrome (HAVS) with HAV-Sentry - the wearable technology that has been designed to prevent damage.

Founded in 1991 and based in Blackburn, Northern Carbide Specialists (NCS) has set the standard for precision and efficiency in the manufacture and regrind of solid carbide and HSS cutting tools.

Nitronic 60® is a wear-resistant, high-temperature stainless steel alloy, known for its exceptional galling resistance and ability to perform under extreme mechanical and thermal stress.

Identifying the most suitable cutting tool for the job is a crucial process. Cutting tools can be made from a number of materials such as high-speed steel, cemented carbide, ceramic, or diamond.

Exactaform PCD Aerospace Drill is an advanced tool specifically designed for Aerospace applications.

The Exactaform PCD Standard Point Drill is an innovative alternative to traditional Aerospace drills.

Exactaform’s PCD 2 Flute Slot Drill offers superior results when machining modern materials like CFRP and GFRP.

Our PCD 2 Flute Ball Nose Milling Cutters are perfect for profile milling applications.

Exactaform’s PCD 3 Flute Slot Drill offers the same improvements as our 2 Flute Drill, but with the benefit of an extra cutting edge.

The PCD cutting edges outlast carbide and coated carbide by up to 10 times, preventing the teeth from breaking down and wearing.

12 flute router surpasses all competitor variations with respect to performance and quality.

A popular tool used by several major aerospace companies for CFRP drilling where high volume production is required.

This tool is a versatile, cost effective solution as a long-life roughing tool, or a small batch finishing tool.

A unique tool designed to combat the abrasiveness of modern aerospace materials, and overcome the challenges of sticky aluminium.

Combining the latest technology patented drill reamer drastically improving productivity rates and decreasing project costs.

Specifically engineered for aerospace materials, the 8 Facet Drill is ideal for CFRP, aluminium, and stacked combinations.

Our Standard Range of Solid PCD Drills is designed to offer reliable, high-quality performance across a broad spectrum of machining applications.