Hardened steel is a high-strength, wear-resistant material designed to withstand intense mechanical stress, heat, and deformation. It is produced through heat treatment processes, increasing its hardness and durability. The hardening process often involves rapid cooling, such as a quenching process, to achieve maximum hardness and improve fatigue resistance.

Machining hardened steel is challenging due to its extreme hardness, high carbon content, and resistance to cutting forces, leading to rapid tool wear, excessive heat transfers, and internal stresses. Without the right tooling, achieving precision and efficiency can be difficult, as fracture toughness and cutting process difficulties can compromise surface integrity.

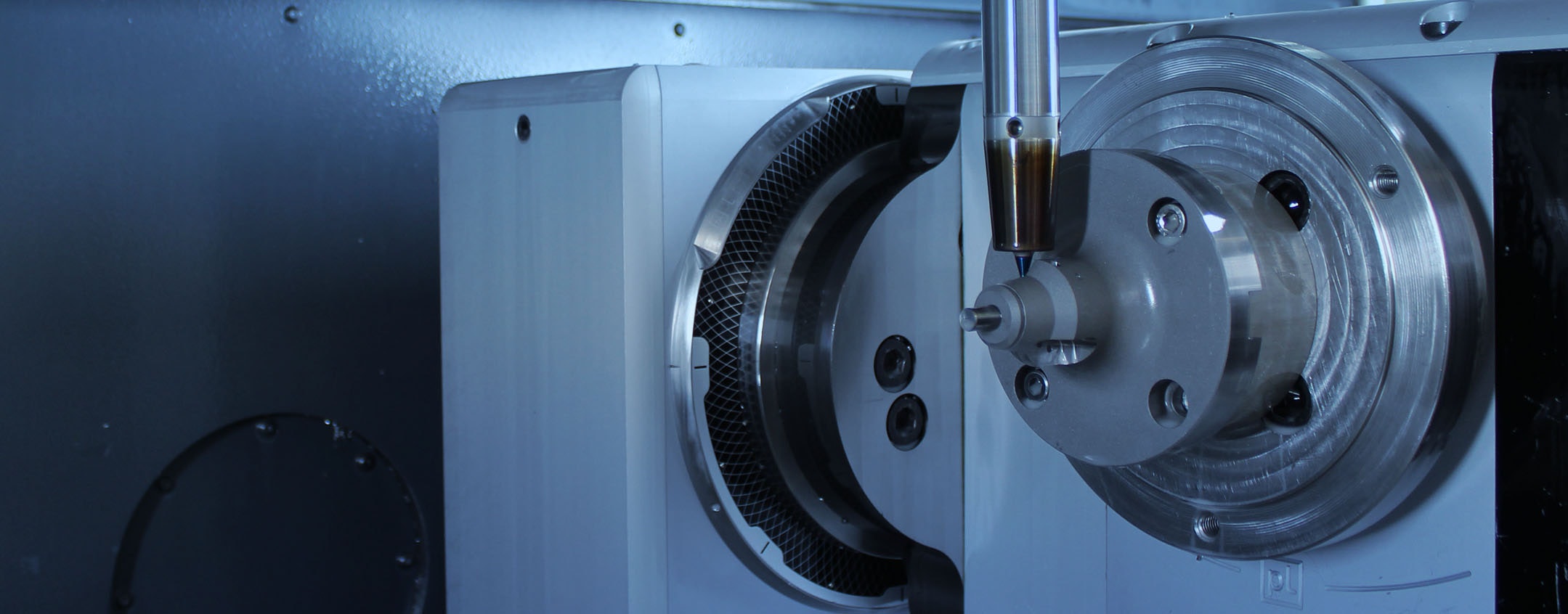

Exactaform’s carbide and CBN cutting tools are engineered to maintain edge integrity, extend tool life, and optimise machining performance. Our advanced tooling solutions ensure optimal machining in high-strength applications. Designed for demanding industries, including automotive, aerospace, and bearing applications, Exactaform’s cutting tools deliver precision, reliability, and efficiency when machining hardened steels.

Our extensive experience in creating rotating tools to customer's individual needs extends to CBN tipped tools for hardened steel machining.

Contact us with your component and material details to get your own engineered solution.

Hardened steel’s extreme hardness and wear resistance require advanced cutting tools that can withstand high cutting forces and heat generation.

Using rigid setups, optimised cutting speeds, and effective cooling strategies is essential to prevent tool failure and maintain process efficiency. Additionally, controlled cooling rates help prevent residual stresses, enhance fatigue life, and maintain machining accuracy, ensuring optimal results in high-performance applications.

Exactaform’s carbide and CBN tooling solutions are designed to maximise efficiency and precision, ensuring superior cutting performance and extended tool longevity when machining hardened steel.

Hardened steel is used in applications requiring extreme durability, wear resistance, and load-bearing capabilities. It is commonly found in high-performance automotive components, where materials must endure constant mechanical stress and friction. Additionally, hardened steel plays a role in industrial applications, where fracture toughness, fatigue resistance, and dimensional stability are critical.

Hardened steel offers superior wear resistance and strength for demanding applications in automotive, and industrial sectors.

1: Dimensional Stability:

Retains its shape and mechanical integrity under extreme forces, high temperatures, and critical cooling rates.

2: Tempering Resistance:

Withstands post-hardening heat treatment and the tempering process without losingsistance – Reduces material deformation, fatigue cracks, and surface degradation, improving component longevity.

3: Heat Resistance:

Maintains high-strength applications at critical temperatures, making it ideal for demanding industrial environments.

4: Machinability with Advanced Tooling:

Requires specialist cutting tools to maintain precision and efficiency.

These properties make hardened steel an essential material for high-performance, load-bearing, and wear-resistant components across industries such as automotive, and other engineering sectors.

Exactaform provides custom carbide and CBN tooling solutions designed to extend tool life, enhance cutting performance, and maintain precision in high-hardness steel machining applications for automotive, aerospace, and industrial components.

With over 45 years of expertise, Exactaform delivers high-performance carbide and CBN tooling for hardened steel machining. Our technical team provides tailored cutting strategies and bespoke solutions, ensuring precision, efficiency, and extended tool life.