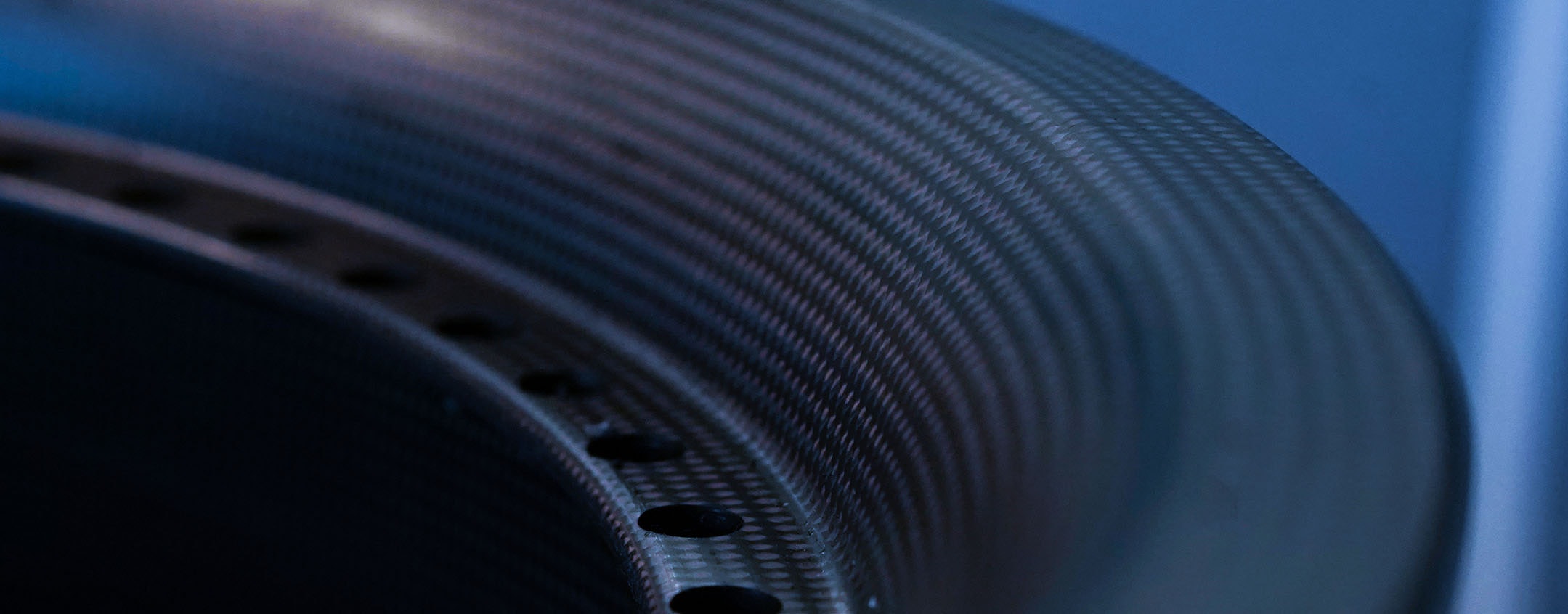

CFRP is an abrasive, layered composite material that requires complex machining capabilities to overcome delamination, fibre pullout, and rapid tool wear. Without the right tools and cutting strategies, cutting CFRP can result in poor edge quality, inconsistent hole finishes, and excessive tool wear. Additionally, its shear strength characteristics and fibre placement issues make precision machining essential in high-performance industries.

Exactaform’s PCD and diamond-coated tools are industry-leading solutions for CFRP machining, offering superior wear resistance, clean cuts, and reduced delamination risks. Our high-performance tooling is specifically engineered for composite machining, ensuring long-term performance, durability in service, and precision machining. Designed for aerospace engineering, industrial applications, and commercial applications, Exactaform’s tooling solutions provide efficiency, reduced tool wear, and machining accuracy in aerospace, automotive, and motorsport industries.

CFRP’s abrasive nature and layered structure present complex machining challenges. The right cutting tools ensure precision, efficiency, and surface integrity, preventing delamination, fibre pullout, and structural failures in high-performance applications.

Choosing the correct cutting tools ensure cleaner cuts, reduced delamination, and extended tool life, helping to minimise material waste, improve production efficiency, and optimise the entire CFRP machining process.

CFRP is essential in aircraft structural components, where its lightweight material properties improve fuel efficiency and performance. Compared to traditional materials, CFRP provides advantages in terms of strength-to-weight ratio, offering stronger performance than many metals. It is used for:

Wing Skins & Panels:

Enhancing aerodynamics, reducing weight, and maintaining mechanical properties. These components are made from carbon fibre materials, designed for high-stress environments.

Fuselage Components:

Providing lightweight durability and structural strengthening in aerospace industry designs, ensuring optimal material consumption.

Military Airframes:

Maximising performance, structural durability, and resistance to thermal expansion in combat conditions. The manufacturing process ensures CFRP meets a wide range of project requirements.

As manufacturers move toward alternative materials, CFRP is a common application in high-performance and motorsport vehicle design due to its lightweight and durable material composition.

Chassis & Bodywork:

Improving durability in service, speed, and fuel efficiency, while reducing weight for better handling. CFRP’s strands of carbon provide rigidity and impact resistance.

Structural Components:

Enhancing crash protection, material properties, and vehicle performance in high-impact conditions. CFRP’s range of properties enables rapid installation and precise engineering.

As industries continue to innovate, CFRP remains a versatile solution for advanced manufacturing, offering superior mechanical strength, flexibility, and efficiency across industrial and commercial applications.

CFRP is used for its exceptional strength-to-weight ratio, making it an ideal material for high-performance and structural applications. Unlike metals, it offers greater stiffness while remaining significantly lighter, providing superior flexural strengthening, tensile strength, and shear strength.

CFRP’s superior material properties continue to make it a cornerstone material in advanced engineering, industrial applications, and high-performance sectors.

Exactaform provides industry-leading bespoke PCD tooling for CFRP machining, known for delivering unrivalled performance in precision, tool life, and surface finish. Our PCD and diamond-coated specials, including drills, mills, countersinks and more, are designed to reduce tool wear, and maximise machining efficiency.

Exactaform is renowned for its market-leading PCD tools for CFRP, offering unmatched precision and durability. With over 45 years of expertise, we design and manufacture tools in the aerospace and automotive industries that deliver superior performance, ensuring clean cuts, longer tool life, and maximum efficiency in high-performance CFRP machining applications