Our tool reconditioning services are designed to bring your used tools back to an "as-new" state, helping you save costs while keeping your production on track.

By choosing to recondition rather than replace, you benefit from improved delivery times and enhanced tool performance, whether you need a single tool restored or a large batch.

Our team can recondition tools from any manufacturer, offering services such as re-brazing, re-tipping, and re-sharpening with exceptional precision. We even provide options to modify your tools for optimised performance, reducing your stock levels and improving productivity. Exactaform's "Refurb or Recycle" program takes a step further by contributing to environmental sustainability, helping you reduce waste and your carbon footprint while maintaining the highest standards of tool quality.

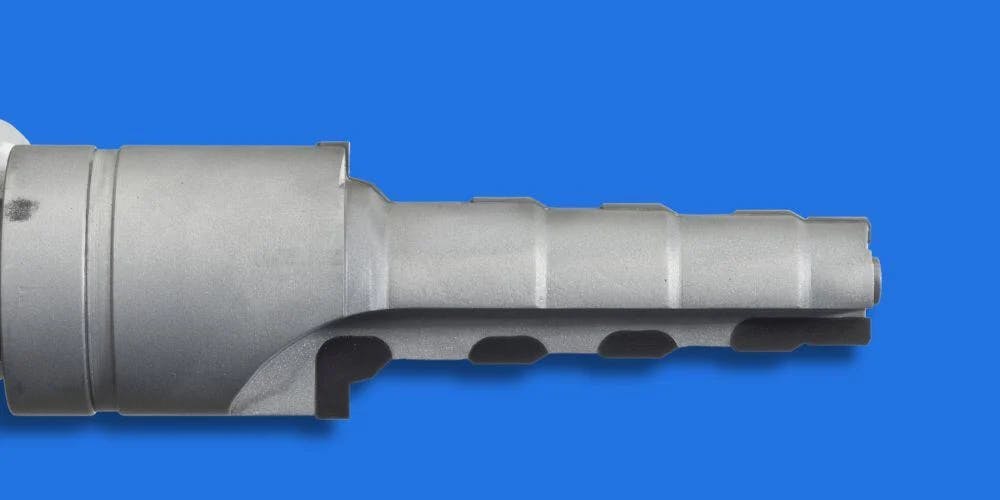

PCD (polycrystalline diamond) tools are known for their durability and resistance to abrasive materials, but they will still need replacing or refurbing from time to time. Our PCD reconditioning program is here to extend that life, using economical methods that restore the tool to its original performance standards.

We assess the level of wear and select the best method to refurbish your PCD tool

Replacing the worn PCD tip with a new one to provide a fresh cutting edge, eliminating wear and damage.

For tools that allow it, we can reuse the PCD tip through re-brazing, reducing costs further.

We ensure every refurbished tool meets exact specifications, giving you peace of mind with each use.

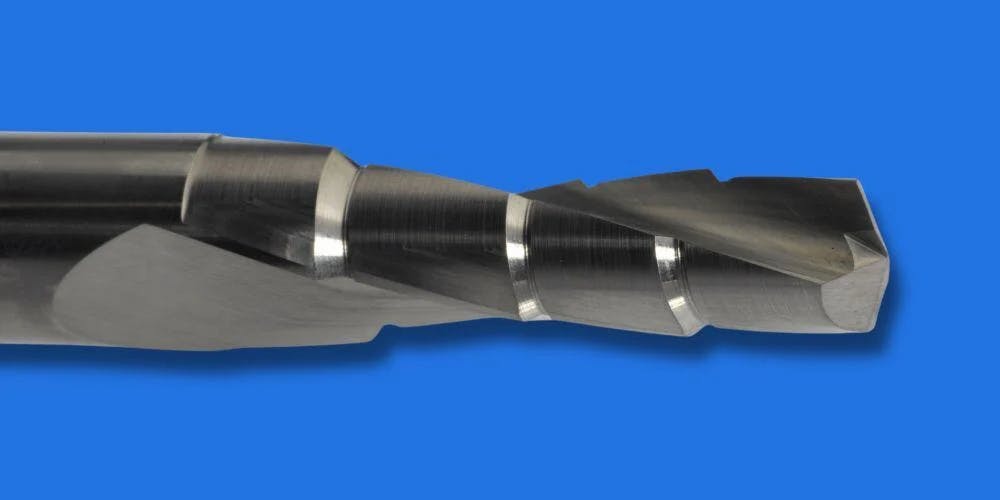

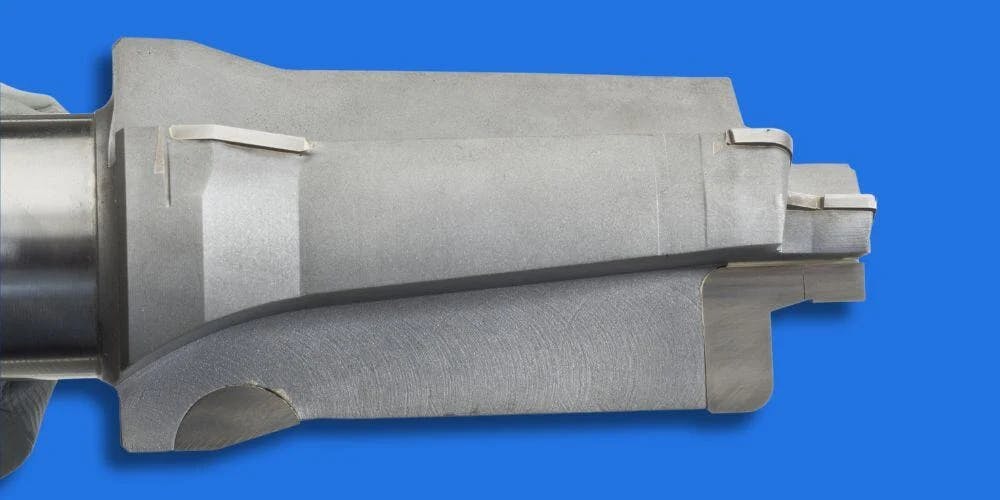

With the right processes, carbide tools can have a significantly extended service life. Our state-of-the-art equipment and skilled engineers can restore step drills, reamers, form tools, core drills, and milling cutters to peak performance

We conduct a detailed evaluation of each cutter to determine the optimal refurbishment approach.

Our team can reverse engineer tools to ensure refurbishment meets exact specifications.

With advanced CNC technology, we achieve consistent accuracy in every refurbishment, providing tools that perform as well as new.

To give you full confidence, we offer a comprehensive inspection report with every refurbished tool.

Whether your tool requires a simple re-sharpening or a complete overhaul, Exactaform’s reconditioning service guarantees quality and consistency.