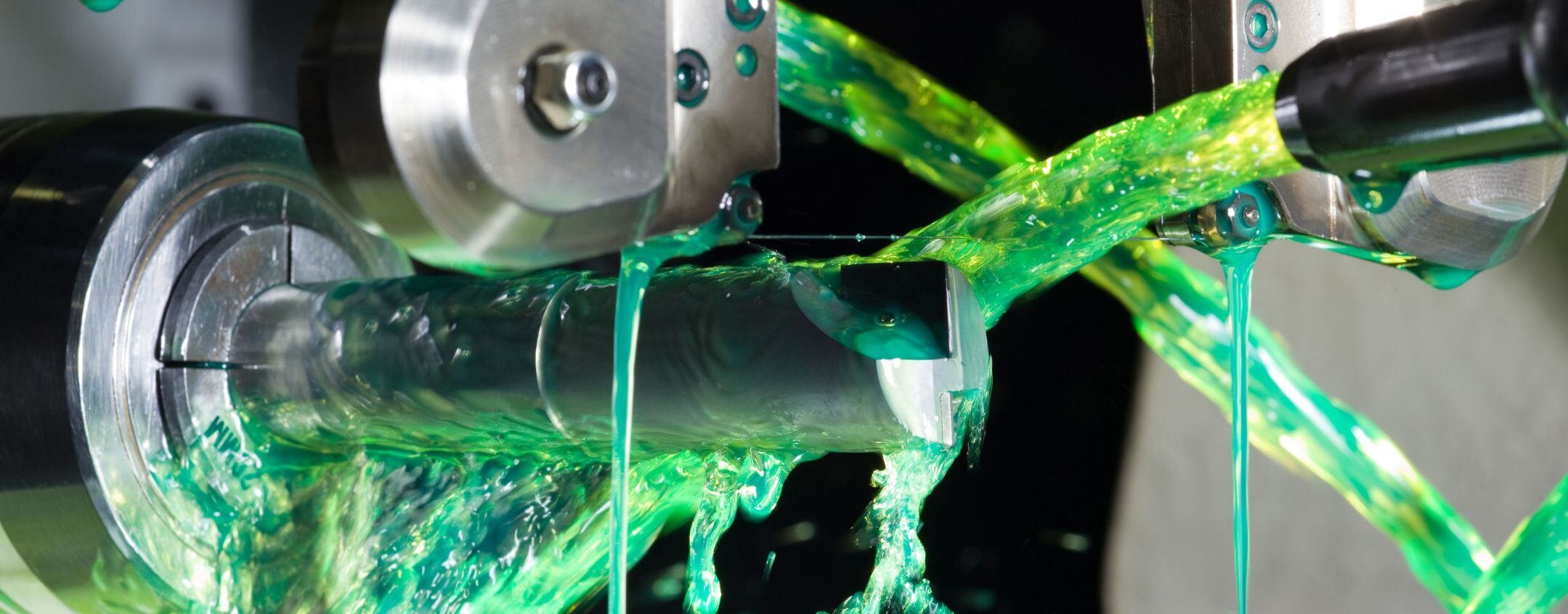

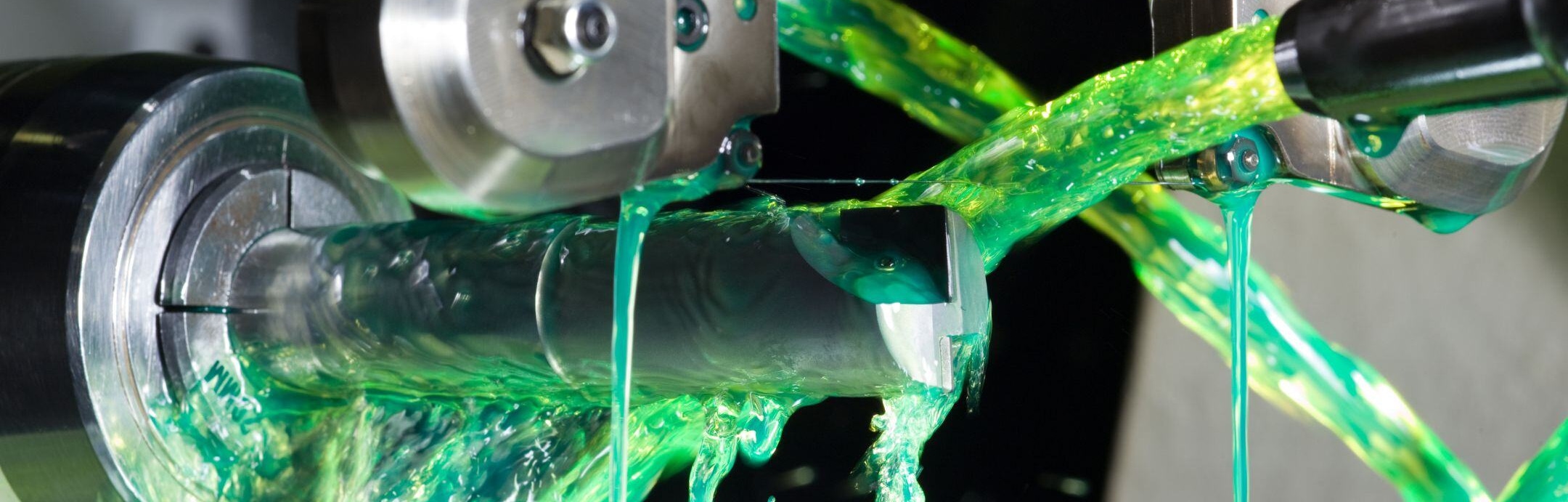

Exactaform’s standard range of PCD cutting tools offers industry-leading durability and performance for applications requiring precision and efficiency.

Our PCD tools are designed specifically for non-ferrous abrasive materials, such as carbon fibre reinforced polymers (CFRPs), metal matrix composites (MMCs) and other challenging advanced materials. With over 40 years of expertise in PCD tooling, Exactaform has created a high-quality, off-the-shelf range ideal for both low and high-volume machining environments.

With our extensive experience and UK-based manufacturing, Exactaform stands out as a trusted partner for advanced PCD tooling solutions. Here’s what sets us apart:

Our team of engineers and technical specialists bring unparalleled knowledge in PCD tooling for aerospace, automotive, and other precision industries.

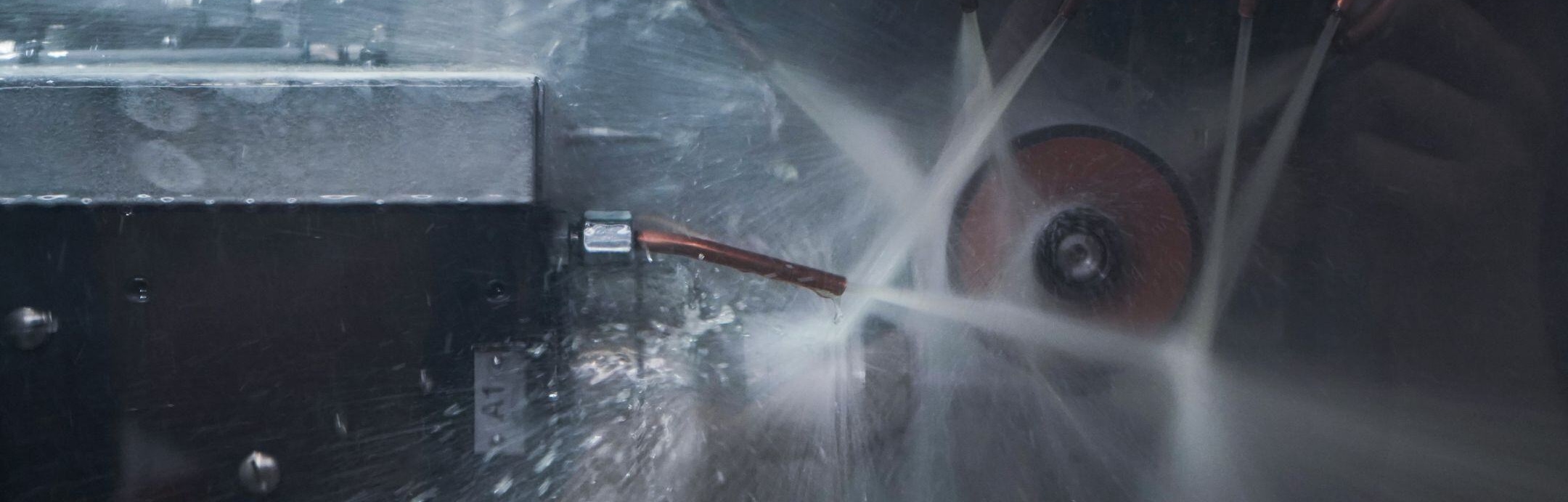

All Exactaform tools are manufactured in our state-of-the-art UK facility, ensuring high quality, quick delivery times, and strict production standards. Our eco-friendly approach to tooling supports sustainable practices without compromising quality.

Our support doesn’t end at delivery. We offer guidance on cutting speeds, cycle time optimisation, and ongoing technical support to maximise the value of your tooling investment.

We are committed to showing our value upfront, which is why we offer a unique guarantee: we guarantee to add value before you spend a single penny with us.

Tool Description

Our PCD Slot Drills feature 2-flute designs with sharp PCD cutting edges for high resistance to abrasive wear. Each drill is manufactured with a precise sharp corner, but for added flexibility, we offer free modification to a customer-specified corner radius.

Machining Applications

These slot drills are ideal for trimming, slotting, and surface machining in CFRPs, MMCs, and other abrasive non-ferrous materials. Offering excellent surface finish and accuracy, they are a cost-effective solution for low-volume machining environments.

Part No. | DIA | LOC | REACH | OAL |

|---|---|---|---|---|

9992 | ⌀2 | 6 | 8 | 60 |

9567 | ⌀3 | 6 | 20 | 60 |

7956 | ⌀4 | 6 | 20 | 60 |

8533 | ⌀5 | 10 | 30 | 100 |

7840 | ⌀6 | 10 | 30 | 100 |

7841 | ⌀8 | 10 | 30 | 100 |

7842 | ⌀10 | 12 | 30 | 100 |

7843 | ⌀12 | 14 | 30 | 100 |

9993 | ⌀16 | 14 | 50 | 50 |

9996 | ⌀20 | 14 | 50 | 50 |

9276 | ⌀1/8" | 0.250" | 0.750" | 3.00" |

9277 | ⌀3/16" | 0.313" | 1.000" | 3.00" |

9278 | ⌀1/4" | 0.375" | 1.250" | 4.00" |

9279 | ⌀5/16" | 0.500" | 1.250" | 4.00" |

9280 | ⌀3/8" | 0.500" | 1.250" | 4.00" |

9281 | ⌀1/2" | 0.550" | 1.250" | 4.00" |

Tool Description

Exactaform’s 2-flute PCD Ball Nose Slot Drills are manufactured with precision, featuring a full-radius ball nose for optimal form accuracy. Designed to withstand abrasive materials, these tools provide an efficient solution for precision machining.

Machining Applications

Perfect for trimming, slotting, or surface machining in CFRPs, MMCs, and other non-ferrous materials, these slot drills ensure a superior surface finish in low-volume machining setups.

Part No. | DIA | LOC | REACH | OAL |

|---|---|---|---|---|

8219 | ⌀2 | 6 | 10 | 60 |

8651 | ⌀3 | 6 | 10 | 60 |

8193 | ⌀4 | 6 | 20 | 60 |

8330 | ⌀5 | 10 | 30 | 100 |

7836 | ⌀6 | 10 | 30 | 100 |

7837 | ⌀8 | 10 | 30 | 100 |

7838 | ⌀10 | 12 | 30 | 100 |

7839 | ⌀12 | 14 | 30 | 100 |

8157 | ⌀16 | 14 | 30 | 100 |

For applications requiring precise thread forms, Exactaform’s PCD Thread Mills are engineered to deliver durability and accuracy. The PCD cutting edges last up to ten times longer than carbide alternatives, resisting tooth wear and breakdown in high-abrasion environments. Used widely in aerospace, automotive, and medical industries, our PCD Thread Mills are ideal for threading CFRPs, MMCs, and other abrasive materials.

Part No. | DIA | LOC | REACH | OAL |

|---|---|---|---|---|

9997 | M4 | 5 | 11 | 100 |

9998 | M5 | 5.5 | 15 | 100 |

9999 | M6 | 6 | 18 | 100 |

10000 | M8 | 8 | 20 | 100 |

10001 | M10 | 8.5 | 25 | 100 |

10002 | M12 | 8.5 | 30 | 100 |

Custom Thread Solutions

We offer customised PCD thread mills from sizes M3 and above. Contact our team for a tailored quote.

Exactaform is recognised as the premier manufacturer of solid PCD drills in the UK. Our solid PCD drills are available as semi-finished blanks, ready for customisation to your specific requirements. These drills are highly popular for their efficiency in abrasive material machining and their availability as off-the-shelf items allows for rapid delivery.

Applications

Our solid PCD drills are optimised for high-performance drilling in aluminium, CFRPs, MMCs, and complex material stacks. We tailor each tool’s geometry to match your specific application needs, and can accommodate custom requests for diameter, length of cut, and overall length. Standard drills are ready for dispatch within 2-3 working days.

General Drilling

Part No. | DIA | LOC | REACH | OAL |

|---|---|---|---|---|

10023 | ⌀3/16" | 30 | 100 | ⌀6 h6 |

10024 | ⌀5mm | 30 | 100 | ⌀6 h6 |

10025 | ⌀1/4 | 30 | 100 | ⌀8 h6 |

10026 | ⌀6mm | 30 | 100 | ⌀8 h6 |

10027 | ⌀5/16" | 30 | 100 | ⌀10 h6 |

10028 | ⌀8mm | 30 | 100 | ⌀10 h6 |

Aerospace Drilling

Part No. | DIA | LOC | REACH | OAL |

|---|---|---|---|---|

10149 | ⌀3/16" | 30 | 100 | ⌀6 h6 |

10150 | ⌀5mm | 30 | 100 | ⌀6 h6 |

10151 | ⌀1/4" | 30 | 100 | ⌀8 h6 |

15152 | ⌀6mm | 30 | 100 | ⌀8 h6 |

15153 | ⌀5/16" | 30 | 100 | ⌀10 h6 |

15154 | ⌀8mm | 30 | 100 | ⌀10 h6 |

Modifications to the standard drill range, such as internal coolant channels or countersink features, can be arranged through our team.

One of the primary benefits of choosing solid PCD drills is their reworkability, allowing up to 40% savings through refurbishment.