The automotive industry is built on efficiency, consistency, and cost-per-part reduction - especially in high-volume production environments. Whether it’s combustion engine parts, EV components, or structural aluminium housings, precision cutting tools are essential for meeting tight tolerances, surface finish expectations, and productivity goals.

At Exactaform, we specialise in high-performance PCD, carbide, CBN, diamond-coated, and HSS cutting tools. Each of our tools are engineered to meet the specific demands of automotive manufacturing, from roughing hardened steel to finishing aluminium castings.

With a focus on reducing cycle times, extending tool life, and increasing repeatability, our tools are used across OEMs, Tier 1 suppliers, and motorsport manufacturers globally.

Exactaform offers a range of advanced tooling solutions that can be manufactured to your exact specifications. Whether you're seeking directional coolant channels, multiple operations from one-shot machining, tight tolerance holes or simply very precise machining, our team can guide you through the process.

Our tools are used in high-volume production, motorsport, and electric vehicle innovation, ensuring manufacturers achieve high performance, repeatability, tool longevity, and cost efficiency.

Exactaform tools are trusted to help produce high-precision automotive components, examples include:

Turbohousings, pump housings, cylinder heads, gearbox housings

Engine blocks, brake callipers

Steering systems, drive shafts

Camshafts, crankshafts

Panelling, engine parts, brake systems, titanium fasteners

We help customers match the best cutting tool to the material they’re machining, ensuring high surface finish, and reduced cycle times.

Widely used in engine housings, structural parts, and EV applications.

Recommended tools: PCD, Diamond-Coated, Carbide

Common in older engine blocks and brake systems.

Recommended tools: Carbide, CBN

Used in drivetrain components, shafts, and performance parts.

Recommended tools: Carbide, CBN

Increasingly used in high-performance and EV applications.

Recommended tools: Carbide

Found in lightweight performance structures and motorsport.

Recommended tools: PCD, Diamond-Coated

Most of our automotive customers require bespoke tooling, whether it’s to hit cost-per-part targets, reduce tool changes, or deliver consistent high volume quality. At Exactaform, we design and manufacture specials tailored to your machining processes. From PCD drills to multi-stage carbide tools, our in-house team ensures you get the right tool for your process.

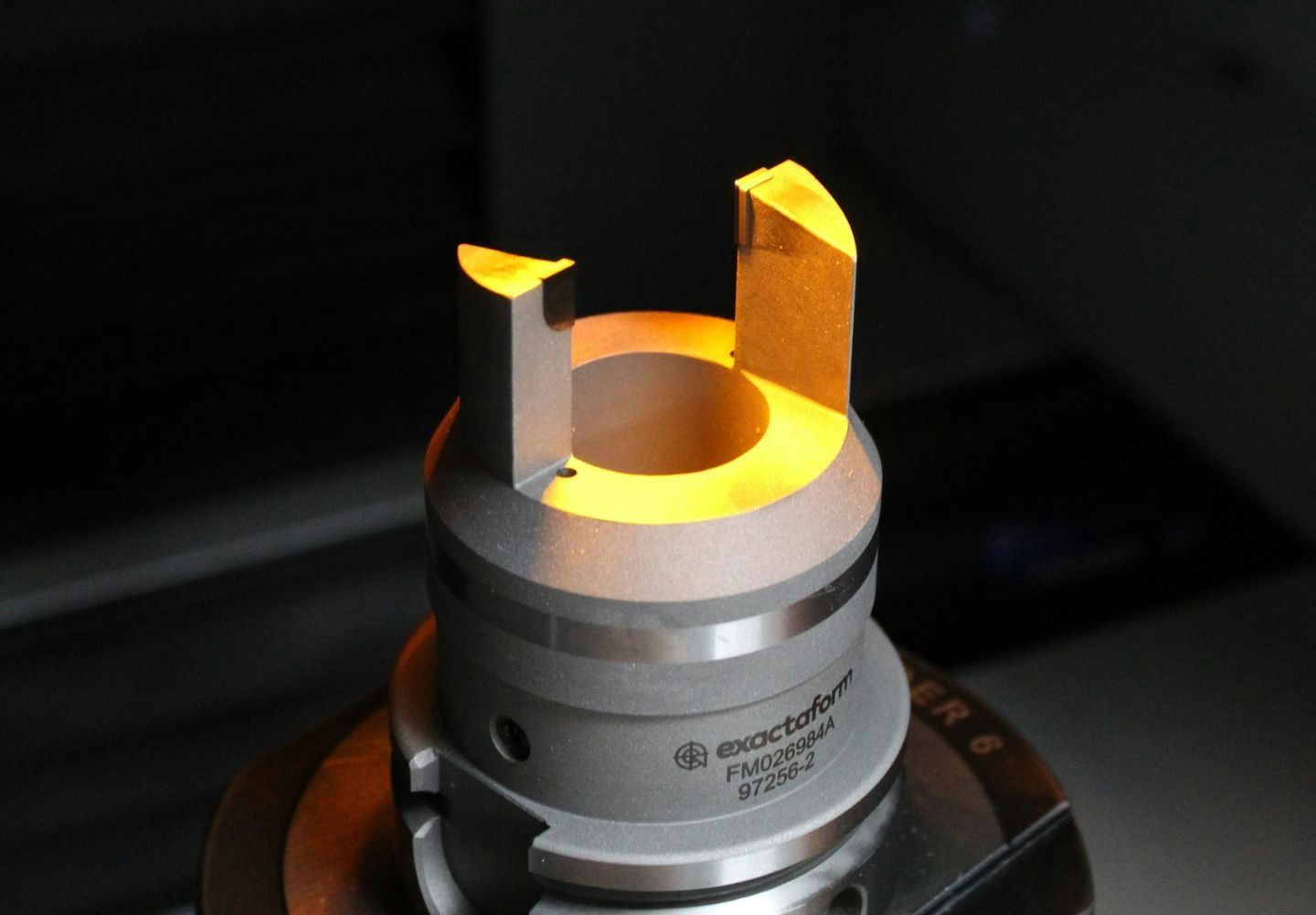

We also offer high-performance standard tools, including our Exactaset face milling system, ideal for flat aluminium components such as valve bodies, cylinder heads, and structural housings.

With over 45 years of cutting tool expertise, Exactaform has become a trusted partner to the global automotive industry, for customers including; Rolls Royce, Mitsubishi, Red Bull Racing, Kawasaki, and Toyota.

We’re known for:

From prototype to production, we deliver tools that meet the highest standards of precision, durability, and speed.

The Exactaset is our modular PCD face milling system, designed for maximum stability, flexibility, and tool life. It’s ideal for flat-surface machining of parts like valve bodies, cylinder heads, and aluminium housings, offering fully adjustable cartridge positions for optimised surface finish.

We offer full refurbishment services including re-tipping, re-brazing, and regrinding, allowing you to reduce long-term tooling costs without compromising on performance.

We can design multi-stage tools such as drill/reamers or mill/reamers, to consolidate processes, reduce tool changes, and increase machining efficiency.

Our technical team works directly with engineers to advise on optimal speeds, feeds, and cutting strategies. We help ensure your tooling setup delivers maximum process security and part quality, while also reducing cycle time and tool wear.

Our application engineers can provide on-site and remote support for tool performance monitoring, cutting strategy reviews, and continuous process improvement, ensuring the tool keeps performing long after it’s delivered.