Exactaform supplies the full WIDIA carbide range in the UK with faster technical response, practical application support, and dependable availability, all from your UK-based engineering partner.

Exactaform supports your machining process with WIDIA carbide tooling as part of complete carbide tooling and cutting tool solutions for modern metalcutting environments. We supply the full WIDIA carbide range in the UK, providing faster technical response, practical application support, and dependable availability from your UK-based engineering partner.

As an industry-leading manufacturer of metal cutting tools, WIDIA delivers cutting-edge technology designed to meet the evolving requirements of the metalworking industry. Manufactured using advanced tungsten carbide grades and coated grades, WIDIA tools are engineered to deliver consistent, high-performance results across CNC milling, turning, drilling systems, and threading applications involving stainless steel, hardened materials, carbon steels, and high-temperature alloys.

Exactaform is the official UK supplier of WIDIA carbide tooling, supporting manufacturers across aerospace, automotive, general engineering, and high-volume production environments. Alongside supply, we provide engineering-led application support to ensure WIDIA metal cutting products are selected and applied correctly for your industrial machinery, machine capability, and production objectives.

To support production planning, we hold UK stock on key WIDIA product lines, offering fast, dependable supply for both standard tooling and specialist requirements.

Exactaform supplies and supports the full range of WIDIA tooling across the UK, covering solid end milling, turning, holemaking, indexable tooling, and tooling systems. With broad coverage across materials and operations, WIDIA tooling solutions are well suited to manufacturers looking to reduce downtime, maintain quality, and improve overall productivity when machining hard materials and complex components.

WIDIA turning tools are engineered for reliable internal and external machining. The range includes boring bars, grooving, and cut-off solutions designed to deliver stable performance, improved surface finish, and extended tool life across a wide range of materials.

WIDIA solid carbide end mills are designed for high-efficiency milling operations. Featuring optimised geometries and effective chip evacuation, they deliver consistent performance when machining hard materials and metal alloys in both metric and inch sizes.

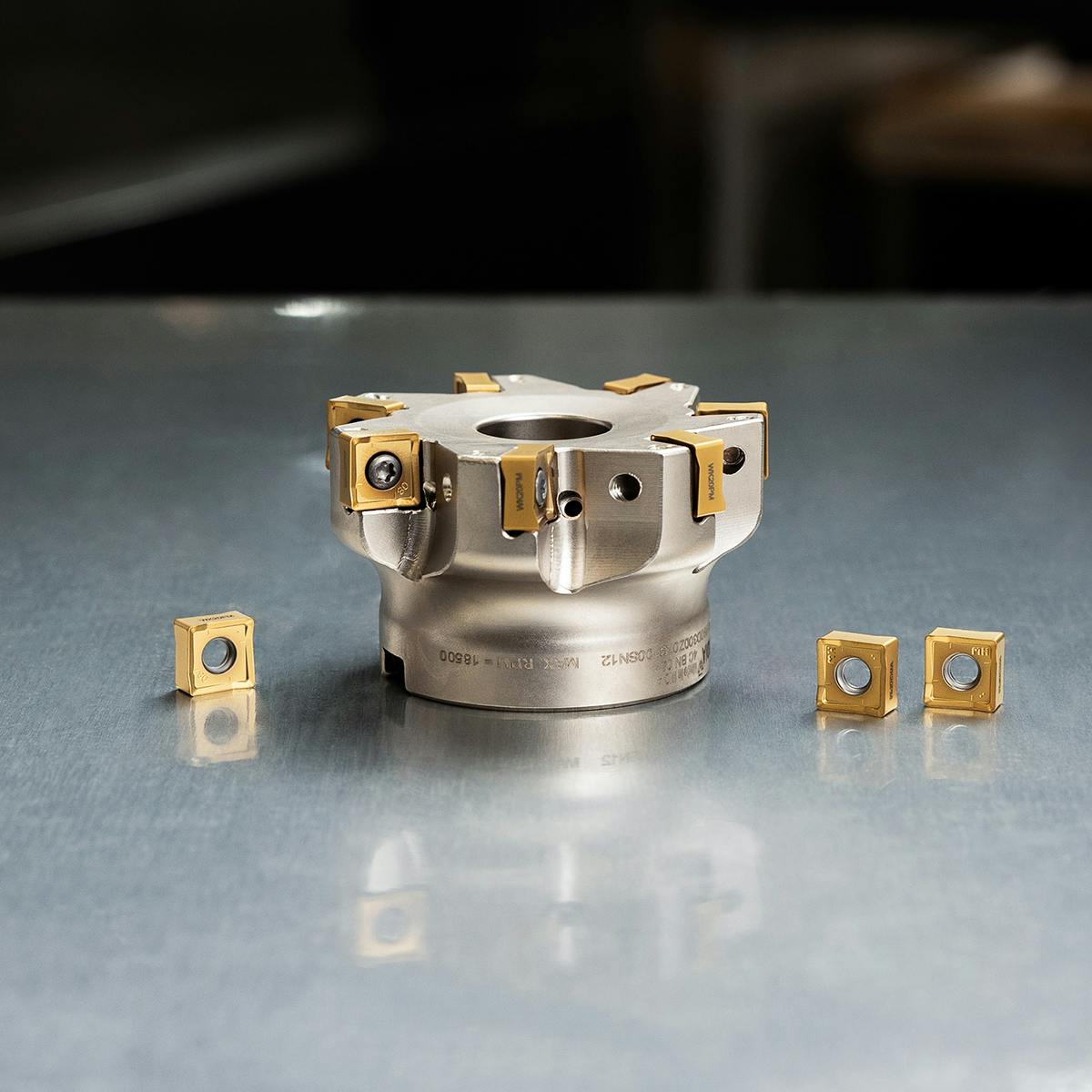

WIDIA indexable milling solutions support high material removal rates and consistent results. The range includes face mills, shoulder mills, and advanced milling platforms engineered for demanding metal cutting applications.

WIDIA holemaking tools deliver accuracy and reliability through a complete modular drilling platform. The range includes drills, reamers, and indexable solutions designed to improve tool life and chip evacuation in challenging materials.

WIDIA tooling systems offer flexibility and performance across multiple machining operations. The range includes tool holders, adapters, collet chucks, and clamping solutions to support secure holding and reduced runout.

WIDIA tapping tools provide dependable threading performance across a wide range of applications. Designed for consistency and durability, WIDIA taps support efficient internal threading in production and general machining environments.

Celebrating a Century of Solutions That Work as Hard as You Do

You don’t need to change your tooling strategy to start a conversation. Exactaform offers an application review designed to provide practical, engineering-led guidance, whether you’re assessing WIDIA carbide tooling or reviewing a broader machining process involving carbide, PCD, Diamond Cut tools, Carbon Split Dies, or mixed tooling environments.

We’ll ask you to provide details of your current operation, material, or challenge. This may include CNC milling, threading tools, indexable milling inserts, solid tooling constraints, or specific metal cutting requirements related to tool life, stability, or cycle time.

An Exactaform application engineer will review the information provided, assess tool suitability, and evaluate machining conditions. This may include reviewing coated grades, cutting tool technologies, precision tooling systems, or alternative approaches within your cutting tool programme.

You’ll receive practical guidance on suitable WIDIA carbide options, feed and speed considerations, opportunities to improve stability or tool life, and advice across carbide, PCD, or custom solutions programs where relevant.

Exactaform supports UK manufacturers with application-specific WIDIA carbide tooling guidance, combining local engineering knowledge with global tooling technology. Our support focuses on cutting tool solutions that align with real-world metal cutting requirements, machine capability, and production goals. Application support considers factors such as helix angle selection, cutting length stability, shank type suitability, chip evacuation, and overall process reliability to ensure consistent results in demanding machining environments.

Exactaform supports WIDIA carbide tooling across a wide range of materials and machining challenges within the metalcutting industry, including:

Tooling recommendations consider chip evacuation, tool length stability, cutting forces, and overall process efficiency.

Exactaform regularly supports manufacturers facing challenges such as:

Submitted reviews are typically assessed by an application engineer within a few working days.