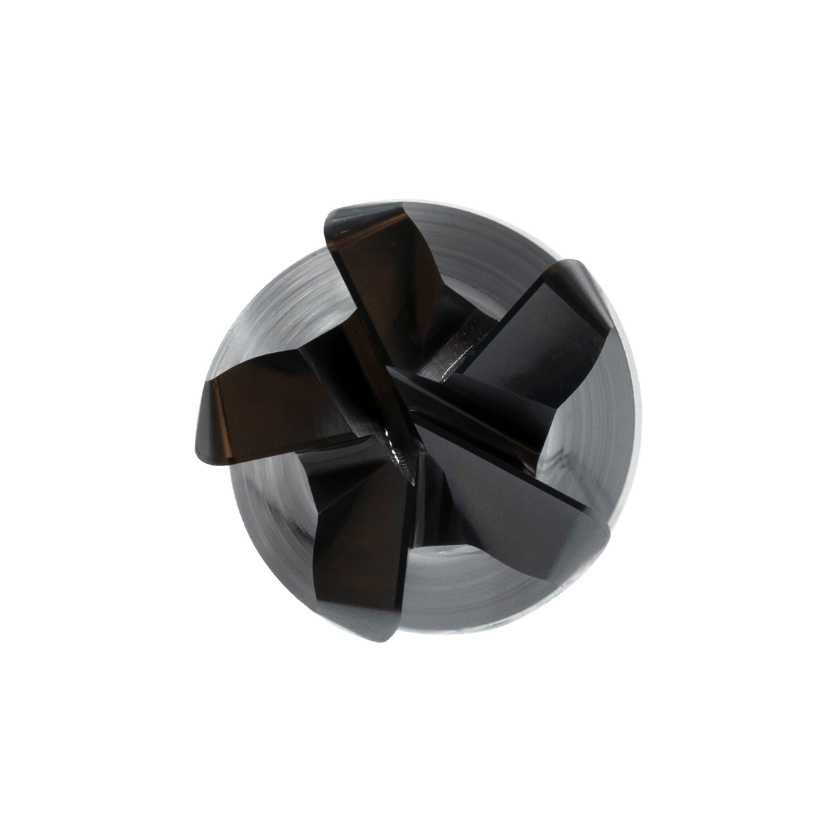

Introducing our premium range of carbide end mills, designed specifically for machining aluminium, titanium and nickel alloys. Developed for the US market, the ExactaMill XE13 & XE22 Series guarantees higher productivity through combination of application-specific designs, advanced geometry, and next-generation coatings.

Whether your needs are removing material quickly or achieving a flawless finish, our tools are engineered to meet the demands of your most challenging applications, offering consistent reliability and outstanding results.

Our carbide end mills are engineered by application with tools geometries for aluminium and titanium and nickel alloys. Each tool is designed to match the specific cutting dynamics, heat profiles, and chip behaviours for efficient removal of the material it is designed to cut.

That means smoother chip evacuation, reduced built-up edge and exceptional surface finish in aluminium. While in titanium and nickel alloys, tool rigidity and controlled cutting edges minimise wear and maintain accuracy under extreme heat and stress.

Our design innovations combine variable pitch flute spacing, reinforced core diameters, and highly polished flutes to balance strength, chip flow, and vibration control. The result is exceptional tool stability and part dimensional accuracy, even on thin-wall machining or high-speed finishing.

This geometry-first approach ensures process security and consistency, allowing you to run faster feeds and speeds without compromising on quality - helping operators push productivity limits confidently and safely.

Our end mills are finished with very latest generation coatings. Our team of engineers have chosen each coating to enhance performance for each material group.

The coatings are tested to ensure longer life, reduced cycle times, and consistent finishes.

Our ExactaMill XE13 and XE22 Series combine all the elements of high-performance machining to deliver measurable improvements in speed, reliability, and finish quality.

Every detail has been designed to help operators achieve higher productivity and extended tool life.

Discover all the details about our carbide end mills in our digital catalogue, featuring comprehensive specifications and a closer look at each product in the range.

Our range includes tools tailored for every stage of the machining process, ensuring optimal performance for both roughing and finishing.

Each tool in this range has been developed with a focus on performance, reliability, and ease of use.

Sophie's Recommendations

Carbide end mills are essential tools in precision machining, especially in aerospace, automotive, and high-performance manufacturing. Selecting the right end mill can significantly impact productivity, tool life, and overall machining efficiency. But with so many variations available, how do you ensure you're using the best tool for the job?