As aerospace and automotive manufacturers continue their pursuit of lightweight, high-strength structures, Carbon Fibre Reinforced Polymer (CFRP) has become the go-to material in component design. Used in fuselage panels and engine nacelles to suspension systems and battery enclosures, CFRP brings a lot of advantaged to modern engineering, but with these advantages also comes significant machining complexity.

At Exactaform, we’ve spent years engineering advanced PCD and diamond-coated solutions for composite materials. In our latest feature with Aerospace Manufacturing magazine, Aerospace Specialist Martin Burns shares:

“Our approach focuses on combining specialised drill geometries with carefully optimised cutting parameters. Geometry plays a key role in reducing thrust and managing chip flow. We also look closely at the use of coolants, where appropriate, and ensure that tools are manufactured to extremely sharp tolerances. For stacked materials, it’s about striking the right balance between cutting performance in CFRP and tool durability in metals like titanium.”

CFRP is a layered, anisotropic material made from carbon fibres embedded in a polymer matrix. While it offers outstanding strength-to-weight ratio and fatigue resistance, it also presents a host of challenges during machining:

Machining CFRP, particularly in stacked combinations with titanium or aluminium, demands tooling designed to navigate each of these variables without sacrificing finish, accuracy, or throughput.

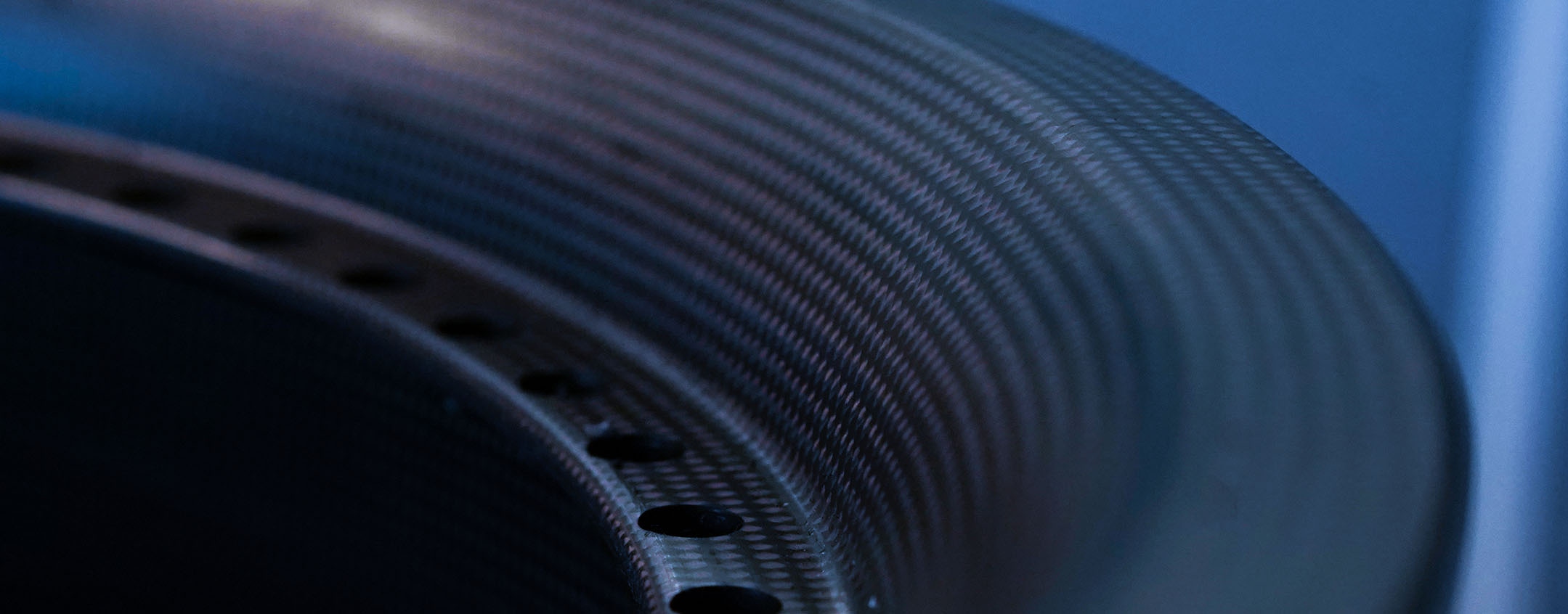

All Exactaform tooling, specialised or off-the-shelf, is developed to perform under the most challenging machining conditions. PCD tooling solutions offer the wear resistance, edge precision, and heat management required for high-volume and precision-critical CFRP applications.

Developed specifically for aerospace CFRP and mixed stacks, Aero-Carb combines advanced carbide substrates with durable diamond coatings. The result is a toolset optimised for composite wear resistance while maintaining the edge integrity needed to hold aerospace tolerances.

Where maximum life and repeatable quality are essential, solid PCD and PCD-vein tooling set the benchmark. These tools are application-led, designed for CFRP and CFRP/Ti combinations where tool stability and resin protection are critical.

Our engineers and experts produce blogs, guides and case studies that help answer the biggest tooling questions.