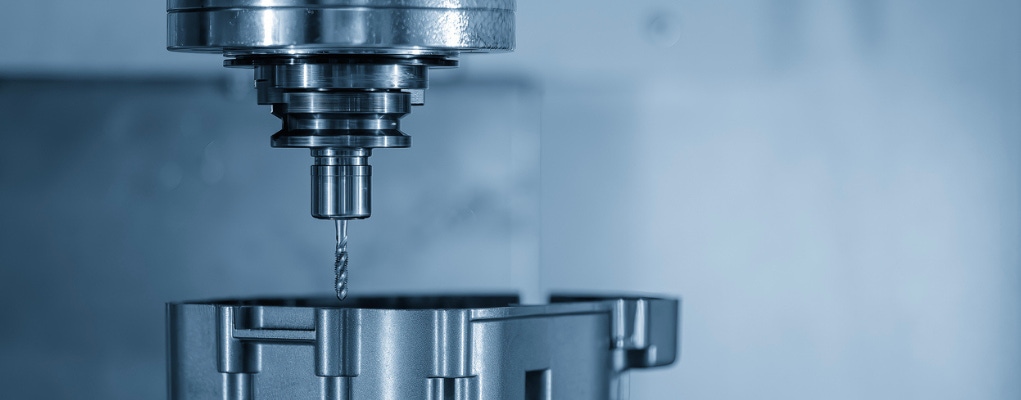

Carbide tooling has become a cornerstone of modern manufacturing, particularly in environments where speed, precision, and durability are critical. As machining demands increase and component materials become harder and more abrasive, many organisations are moving beyond the limitations of traditional high-speed steel (HSS) tools and adopting carbide-based solutions.

This article explains why carbide cutting tools consistently outperform alternative tooling in high-speed, high-temperature, and abrasive machining operations, and how that performance translates into long-term cost efficiency and improved production outcomes.

Supplied across manufacturing sectors by Exactaform, carbide tooling plays a central role in precision manufacturing and advanced CNC machining strategies.

Carbide tooling is typically manufactured from tungsten carbide, a composite material formed by binding extremely hard tungsten carbide particles with a metallic binder. The result is a tool material with exceptional hardness, strength, and thermal stability.

Unlike high-speed steel, carbide retains its cutting edge at much higher temperatures. This makes carbide material especially effective in demanding machining operations where heat buildup and abrasion quickly degrade conventional tools.

Modern options range from solid tungsten carbide tooling to carbide-tipped cutting tools, with specialised designs such as micro tungsten carbide tools for precision work.

One of the most significant carbide tooling benefits is the ability to operate at much higher cutting speeds and feed rates.

In CNC machining and CNC milling, carbide tools allow:

Where high-speed steel tools are limited by heat softening, carbide’s heat-resistant properties enable consistent performance in high-speed milling and aggressive machining strategies.

Carbide tools offer exceptional wear resistance, particularly when machining abrasive materials such as stainless steel or hardened alloys. This resistance to edge breakdown allows carbide tools to maintain sharpness far longer than HSS tools.

Extended tool life means:

For CNC environments running continuous or unattended cycles, this reliability directly improves production efficiency.

Maintaining a sharp cutting edge is critical to achieving a high-quality surface finish. Carbide tools excel here due to superior edge retention and consistent geometry.

In precision machining, carbide end mills, milling cutters, and drill bits produce:

This is especially valuable in industries where cosmetic finish and dimensional accuracy are critical.

Heat is one of the primary causes of tool failure. Carbide’s thermal stability allows it to withstand extreme temperatures generated during machining without losing hardness.

This makes carbide particularly effective for:

While cutting fluid can help manage heat, carbide’s inherent resistance reduces reliance on coolant and improves process stability.

Carbide tooling is well suited to a wide range of modern manufacturing processes, from general metal cutting to advanced CNC production.

Common applications include:

Whether used in traditional machining operations or advanced automated cells, carbide supports consistent, repeatable results.

Compared to HSS tools, carbide offers:

Although carbide tools typically have a higher upfront cost, their performance delivers strong long-term cost efficiency.

Reduced tool consumption, fewer machine stoppages, and higher production output often result in a lower cost per part. For organisations focused on scaling production or improving process reliability, carbide tooling represents a strategic investment rather than a simple consumable choice.

Carbide tooling underpins modern precision manufacturing strategies. By enabling higher speeds, tighter tolerances, and consistent results, carbide tools allow manufacturers to fully utilise the capabilities of advanced CNC machining centres.

When paired with optimised tool paths, correct feeds and speeds, and appropriate coatings, carbide tooling becomes a key driver of production efficiency and quality.

The core carbide tooling benefits lie in performance, reliability, and efficiency. From superior wear resistance and thermal stability to higher cutting speeds and improved surface finish, carbide consistently outperforms alternative tooling in demanding environments. For manufacturers looking to upgrade tooling, improve output, or machine challenging materials more effectively, carbide tooling offers a proven path forward.

To explore available options and applications, see Exactaform’s guidance on Carbide Tooling and Precision Manufacturing Solutions, and identify where carbide can deliver the greatest impact in your machining operations.

Our engineers and experts produce blogs, guides and case studies that help answer the biggest tooling questions.