At Exactaform we pride ourselves on our amazing people. With over 70 employees we are always looking to bring in new additions to our team.

Exactaform are a constantly growing company, often looking for new additions to our amazing team. If you think you would fit well with our culture and values, feel free to apply to one of our open positions. hello

John Inglis founded Exactaform in 1979, renting a single machine and an office.

Over the last four decades, we’ve grown to employ over 70 individuals in our purpose-built facility in Coventry.

Finding a career that’s right for you, where you fit in and excel, is essential.

It’s just as important for us, too, that our people have a sense of belonging.

To help you understand if Exactaform is right for you, we've outlined our six core values. You’ll be a great fit here if they resonate with you too.

“There are some big reasons why I like working here: I appreciate the good relationships, the sense of control, and the flexibility to make changes without difficulty.

The company is expanding and improving, which we’re all passionate about driving forward. Plus, John and Jamie always reinvest in the company, ensuring tomorrow, rather than today, is secured.

Our staff and the culture here are different, too; it isn’t too corporate or restrictive. But, it’s the work-life balance and positivity that really stand out. It really is very good.

Now, I get to watch my grandchildren grow up and help others develop at work. I’ve mentored eight people now, passing my knowledge to a new generation.”

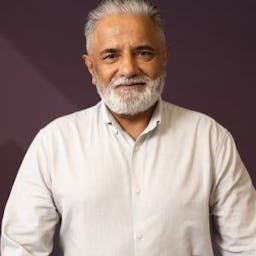

Ricki Nagra

Operations Director

We’re always looking to welcome the best people into our organisation.

Having now employed over 70 team members, and interviewing countless, we have put together a simple but effective application process that automates all.

If you think you match up well to a role and our culture, upload your CV.

If chosen, a relevant team member will arrange an initial phone or video call.

Some roles require you to complete a skills test in your relevant area.

You’ll then be invited for a face-to-face interview at our facility.

After a successful interview, you’ll enrol in a comprehensive onboarding programme for approximately 12 weeks.

Exactaform will provide training, support and mentoring to ensure your success in your role.